Flender

Flender stands for comprehensive knowhow in all questions of mechanical and electrical drive technology and for the best quality in products and services.

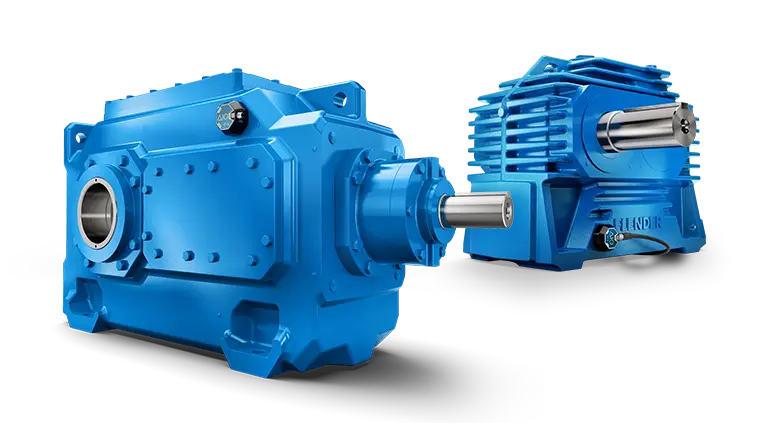

Gear Units

FLENDER ONE

FLENDER ONE® is the new platform for the best industrial gearboxes from FLENDER. As single-stage and multi-stage gearboxes, they are suitable for more than a hundred applications.

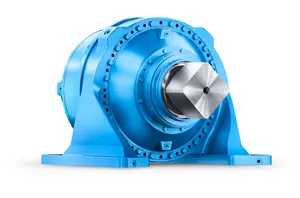

PLANUREX 2 Standard Series

The PLANUREX® 2 series has not only proven its worth over the course of many years in a large number of applications and under the most severe operating conditions. The units’ high quality and reliability have also allowed them to set global standards.

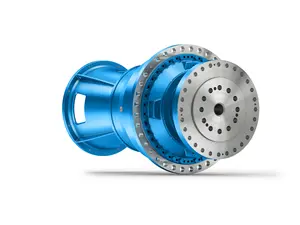

PLANUREX 3 Standard Series

PLANUREX 3 offers a complete, fully standardized planetary gear unit portfolio, combined with short delivery times worldwide, an excellent price/performance ratio and very high modularity.

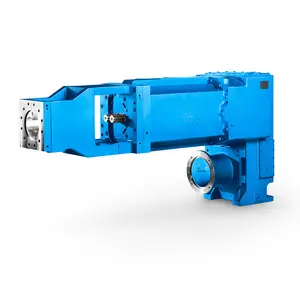

DMG2 Tube Mill Gear Units

tube mills belong to the largest driven machines. They crush minerals (ores or cement clinker) by impact and friction until the material is pulverized.

GEAR UNIT FOR AGITATOR

Agitators and agitator tanks are used in chemical, pharmaceutical, cosmetic, and food processing applications. The diversity of the application requirements and the media employed necessitate customized plant designs.

Paper Machine Gear Units

The drive units for papermaking and finishing plants vary considerably with regard to type and size.

Cooling Tower Gear Units

Wet Cooling Towers are those buildings where the water that was heated by industrial or power generation processes is cooled, again.

Bucket Elevator Gear Units

Bucket elevators serve to vertically transport large masses of bulk material to different heights without creating dust, then dump it. The height to be overcome is frequently more than 200 meters. The weights to be moved are enormous.

GEAR UNIT FOR BELT CONVEYOR

As a leading provider of drive technology for material extraction we are very familiar with all the requirements of mine operation.

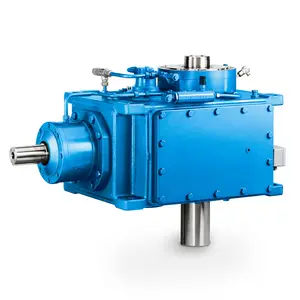

Helical Gear Units with Large Center Distance

Alongside the extensive range of extremely compact standard gear units Flender offers application-specific gear units with a large overall center distance that enable parallel fitting of motor and winding drum, even with large drum and motor diameters.

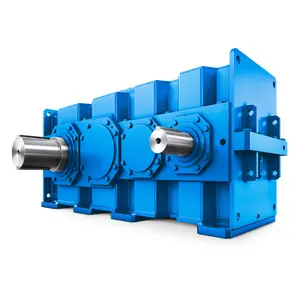

Helical Gear Units and Bevel-Helical Gear Units

The FLENDER® helical and bevel-helical gear unit portfolio is by far the most comprehensive range of industrial gear units in the world. It includes a multifaceted range of universal gear units, application-specific gear units and customer-specific solutions.

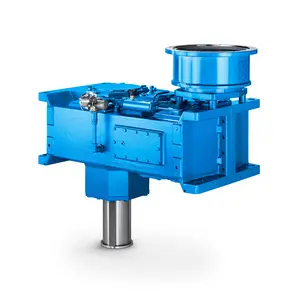

GEAR UNIT FOR AERATOR

An aerator is an impeller in the biological part of a sewage treatment plant. It swirls the surface of the water so that it is enriched with oxygen. This activates the bacteria, so that the biodegradable constituents are removed from the sludge.

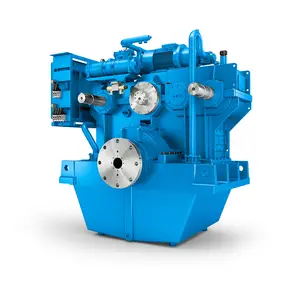

NAVILUS Single input / output marine gearboxes

Single input/single output marine gearboxes are used in river boats and coastal vessels, but also in ocean-going vessels. Depending on the application they can be built with vertically, horizontally or diagonally offset shafts.

NAVILUS Multiple Input / Single Output Marine Gearboxes

Multiple-input/single-output marine gearboxes direct the output of several diesel engines or electric motors to a propeller. Here, different drive concepts can be implemented.

NAVILUS Marine Gearboxes for Dredgers

Suction hopper dredgers are used for the recovery of raw materials and for extension of water shipping lanes. Driven by their own propulsion system the dredger move to the extraction area where they start removing dredged material from the water bottom or waterway beds.

NAVILUS Generator Gearboxes

Generator gearboxes can be used for the low-cost production of electricity on board. They are used with low-speed diesel engines and can be used for generator operation as well as for PTI/PTH operation (emergency operation).

PLANUREX Central Mill Gearboxes

Harsh working conditions and high dust concentrations in the production of cement, limestone and gypsum place high demands on the drive system In the case of central drives, the mill is driven from the end face.

KMP Vertical Mill Gearboxes

The KMP series offers high flexibility with constant product quality for every kind of coal mill. 17 sizes in a torque range of up to 530,000 Nm (operational torque) leave nothing to be desired.

KMPS Vertical Mill Gearboxes

The reliability of each component as a crucial aspect of plant availability and the life cycle cost of drive equipment has a significant impact on the productivity of a cement production.

Double Screw Extruder Gearboxes

FLENDER helical gear units for double-screw extruders with parallel drive shafts and the same direction of screw rotation are available in several sizes in the performance range between 200 and 35 000 Nm per shaft and for up to 20 000 kW.

Single Screw Extruder Gear Units

In the manufacture of rubber and plastics, the great variety of materials requires very high precision of the processing machines.

Jack-up rigs

Jack-up rigs are used to search for oil and gas deposits down to a maximum water depth of 160 m. Tugboats or special transport vessels tow the rig to its drill location.

PLANUREX Gear Units for Travelling Gears

Bucket wheel excavators and spreaders need to travel to their site of operation on their own. The highest loads occur if a difference in height has to be passed in a cornering.

PLANUREX Gear Boxes for Slewing Gear Rrives

Slewing gear drives are used to position driven machines. They are proven in many different applications, such as cranes, excavators, and drilling platforms. FLENDER gear units for slewing gear drives have a modular design.

PLANUREX Gear Units for Bucket Wheels

The gear units are located at the end of the bucket wheel excavator boom, level with the hub, and must therefore be as light as possible.

PLANUREX Roller Press Gear Units

Uneven loads, extreme axial and radial forces, high dust generation – the grinding of iron ore, limestone and clinker is marked by harsh working conditions.

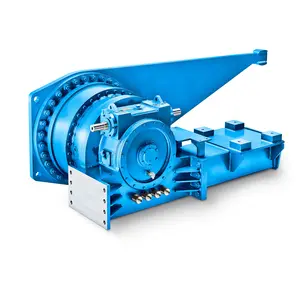

Flender MultipleDrive Gear Units for Vertical Mills

In the cement industry too demand has risen over the years. As a result there is an urgent need of highly available and very high-performance production systems. However, this performance must not be attained at the expense of efficiency.

NAVILUS 2-Speed Gearboxes

In the marine propulsion technology sector it is important to operate a ship’s main engine over long periods at the most efficient operating point possible.

PLANUREX Individual Drive Gear Units for Sugar Mills

The immediate advantages of using PLANUREX® 3 gear units lie in the cost benefits for drive systems and driven machines.

KM2P Vertical Mill Gearboxes

In response to customer requirements we have, with the KM2P gear unit generation, technologically perfected our solutions for the 2,000 to 9,000 kW power range in particular.

PLANUREX Central Drive Gear Units for Sugar Mills

FLENDER gear units are used in the manufacture of sugar from sugar beet and sugar cane and through their optimised design help to save energy.

FLENDER ONE

A new era of industrial drive technology: individual, efficient, smart. FLENDER ONE® is the new platform for the best industrial gear units from the Flender line. Available as single-stage and multi-stage solutions, these gear units are suitable for over 100 applications.

Couplings

Highly Flexible Couplings

Highly elastic FLENDER couplings are well-suited to connect asymmetrically operating machines. They are used preferably in periodically stimulated systems.

Railway Couplings

Whether between motor and gear unit or between gear unit and axle – FLENDER rail couplings have proven themselves thousands of times in virtually every kind of rail vehicle worldwide.

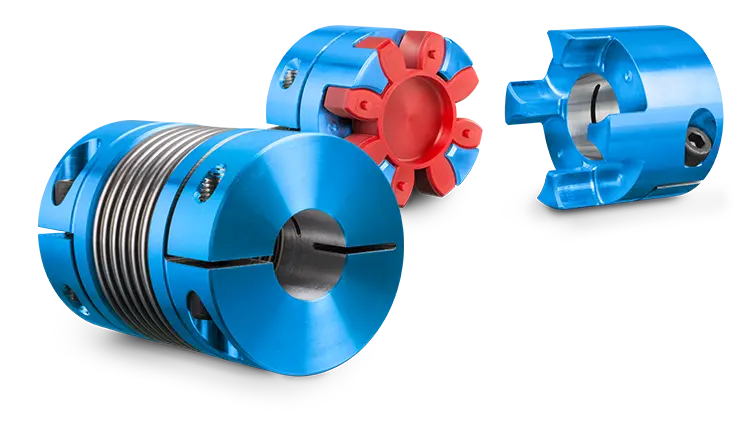

Backlash-Free Couplingse

Our couplings serve as a modular interface between motor and work machine to ensure reliable and backlash-free power transmission in servo- and positioning drives

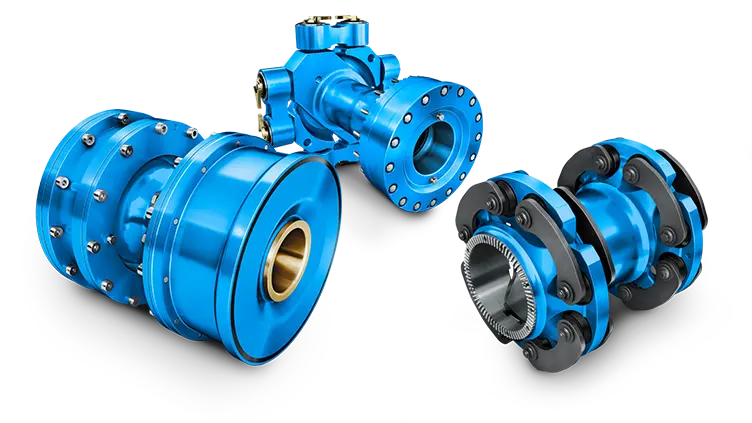

Hydrodynamic Couplings

Smooth start, overload protection, torsional vibration damping – FLUDEX fluid couplings enable torque-limited start-up and have very low slippage at nominal loads.

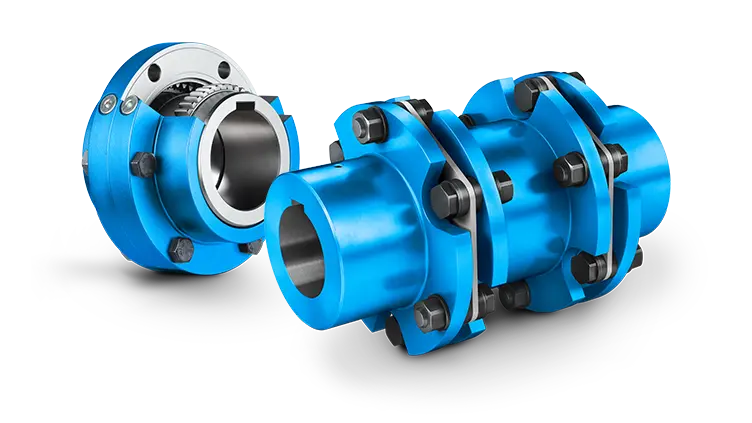

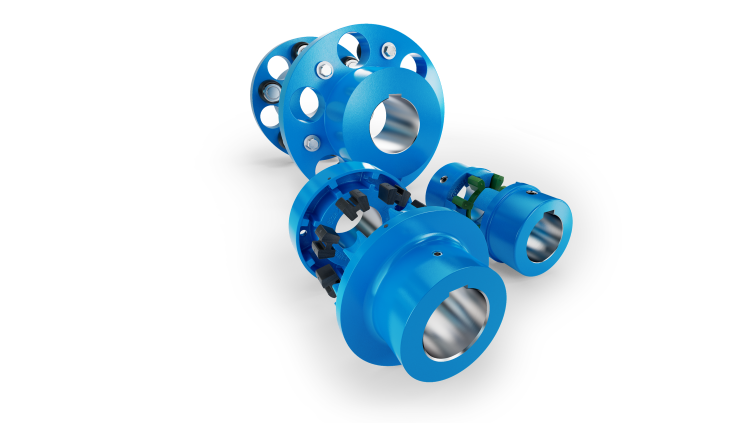

Torsionally Rigid Couplings

Our compact steel couplings provide highly precise transmission of high torques especially under harsh operating conditions and at extreme temperatures.

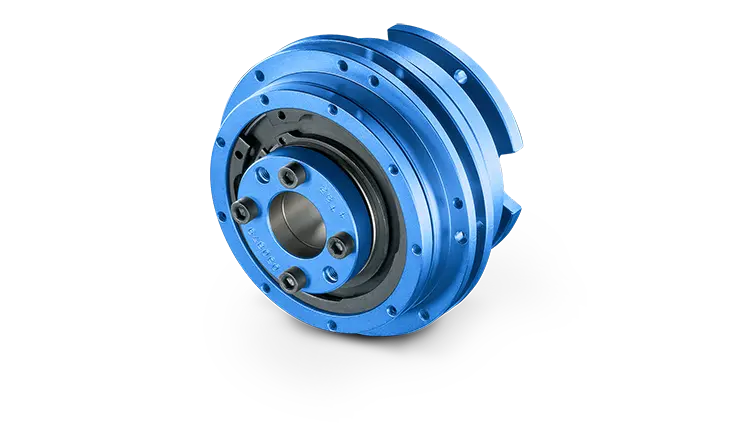

Safety couplings

Our safety couplings ensure ideal overload protection in the drive train, and precise disconnection in the event of an overload.

Flexible Couplings

Elastic FLENDER couplings are mateable and easy to assemble. The elastomer element compensates for shaft misalignment and absorbs impacts from the motor or work machines.

Additional Components

Oil supply system

FLENDER oil supply systems are used for cooling and/or lubricating gear units. Flender uses products which have been specially selected from the market supply, and are made and tested in accordance with Flender specifications. They have been accepted for the planned application.